Anyone who owns an excavator can tell you that they are expensive machines to own and run. When you’ve spent so much money on a machine, you want it to last as long as possible. This can be difficult if you don’t know how to maintain them properly. They’re made with many mechanical parts that require proper oiling, greasing, and cleaning, so you want to ensure that you’re doing the correct upkeep.

Improper maintenance of excavator often leads to excessive wear and tear, which can cause costly repairs and downtime. That’s why it’s important to properly maintain your equipment — before it hurts someone (or cost you thousands of dollars!)

Here are six tips to help prolong the life of your excavator and minimise wear and tear:

1. Regular Excavator Inspection

Every shift should start with a walk around to check filters and fluid levels. Watch for leaks, damage, or debris build-up. If you find any leaks, have them repaired as soon as possible. Also, check for loose screws or seals that let water in. Ensure that all bolts are tightened before use, especially if you’re working in rocky or sandy terrain where things can loosen up quickly under stress from shifting soil conditions (or other factors). Here are some additional points for inspection:

- Regularly check the oil level in your excavator and its coolant levels—you don’t want them running low!

- Don’t forget excavator undercarriage maintenance. Make sure your rollers are clean and can turn freely. If they aren’t, a roller could get stuck and cause the track to wear out. Don’t let debris build up, so it doesn’t wear down the rollers more than necessary.

- Fill up at the end of each day to keep condensation from forming in the tank. Doing so can prevent damage to the fuel system and cause expensive repairs.

2. Grease for more ease

Don’t skip the greasing part. It’s cheap preventive maintenance that keeps your bushings, bearings, and pins running smoothly.

Grease is essential for all pins and bushings. Every day, operators should lubricate all pins and bushings. The operator’s manual will indicate each grease spot and provide grease quantity and quality recommendations. If more than one person uses the same machine, you can mark less obvious grease points, such as the turntable bearing, with orange marking paint around the grease nip to remind all users to do this job. As with inadequate lubrication, excessive lubrication might be problematic. One to three doses of grease are often enough. Utilising more wastes money and poses a potential environmental threat. It can also lead to a considerable mess.

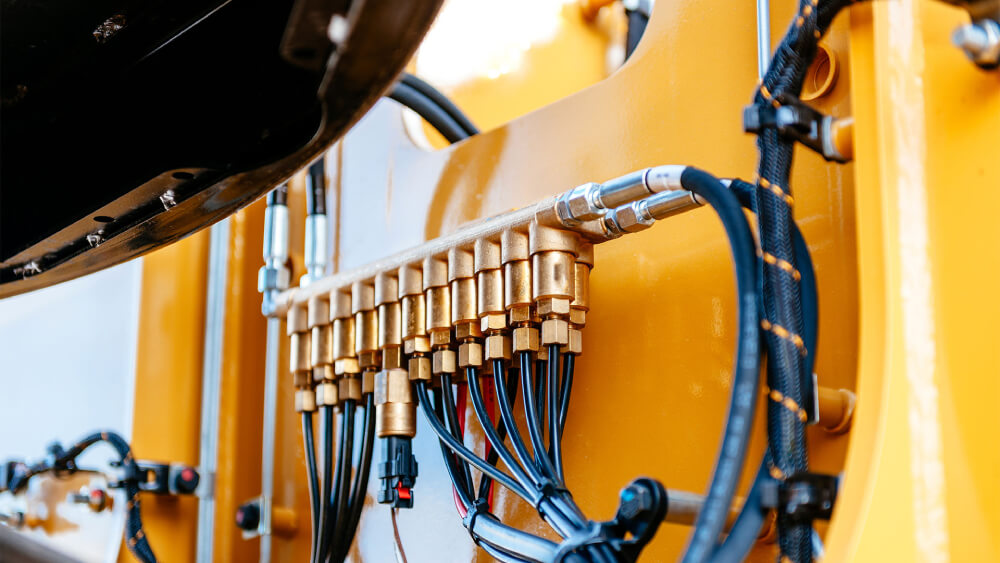

3. Inspect the Hydraulic Oil

Even though hydraulic oil may look clean, just like engine oil, it breaks down over time and loses its viscosity and ability to keep dirt and debris in suspension. Clean oil protects all the parts that move in the system. Most hydraulic failures can be traced back to dirty or even the wrong type of hydraulic oil.

One of the many important things that hydraulic oil does is soak up moisture in the system and keep it from getting into the hydraulic parts. You might not think that rust is a problem in a hydraulic system that is always full of oil and is always sealed, but it is. Service workers have taken apart broken hydraulic pumps and parts of the hydraulic system and found rust on the moving parts and the housings.

Don’t make the mistake of thinking that hydraulic oil is good just because it looks good. When hydraulic oil gets cloudy, it’s long past changing time, and it can’t protect the parts of the hydraulic system as well as it should. Most equipment makers recommend changing hydraulic oil every 2,000 to 4,000 hours, but every machine is different. Your owner’s manual will tell you when your car needs to be serviced and what kind of oil it needs.

4. Check track tension

Track tension is an often neglected service point on excavators. A loose track will accelerate wear, resulting in unneeded downtime and a halt in production. Likewise, an overly tight track may significantly increase the wear on other track system components, such as traction motors, sprockets, and front idlers. In short, too much tension can cause bushings and sprockets to wear out faster, and too little tension can cause the undercarriage to be stressed and waste horsepower.

Refer to the operator’s manual and regularly verify track sag measurements to guarantee the correct track tension.

Incorrect track tension may result in increased track wear. That’s why it is essential to maintain the proper tension. The basic rule of thumb is to run the tracks a little looser while operating in muddy or soft conditions.

5. Always maintain records!

Record keeping may be the most tiresome and time-consuming duty. Still, up-to-date service records and invoices for oil, filters, and repairs can provide essential information for evaluating the remaining useful life of your equipment in the future. Eventually, all equipment will reach the end of its service life. However, if you keep correct and accurate records, you will have a basis for evaluating the machine’s performance and deciding whether to purchase the same manufacturer’s product again or switch to a different brand.

When working with your dealer to resolve a problem with your machine, proper service records are also helpful. Accurate records will demonstrate to both your dealer and the manufacturer that you can care for your equipment and service it as needed.

This rule is important whether you have a whole fleet of excavators or just one. Good service records might also aid in increasing resale value.

6. When in doubt, consult the professionals for excavator servicing

Work with your dealer to make sure that maintenance is done at the right times and check the manual and machine decals for recommended maintenance times and lubrication charts.

Make sure you have a trained professional perform any major excavator repair or replacements on its engine, transmission, or other critical parts—even if they aren’t necessarily broken yet!

If you have any more questions, feel free to reach out to us here. We’ll be with you as soon as we can.